Curiosity Lab + Open Bench Project

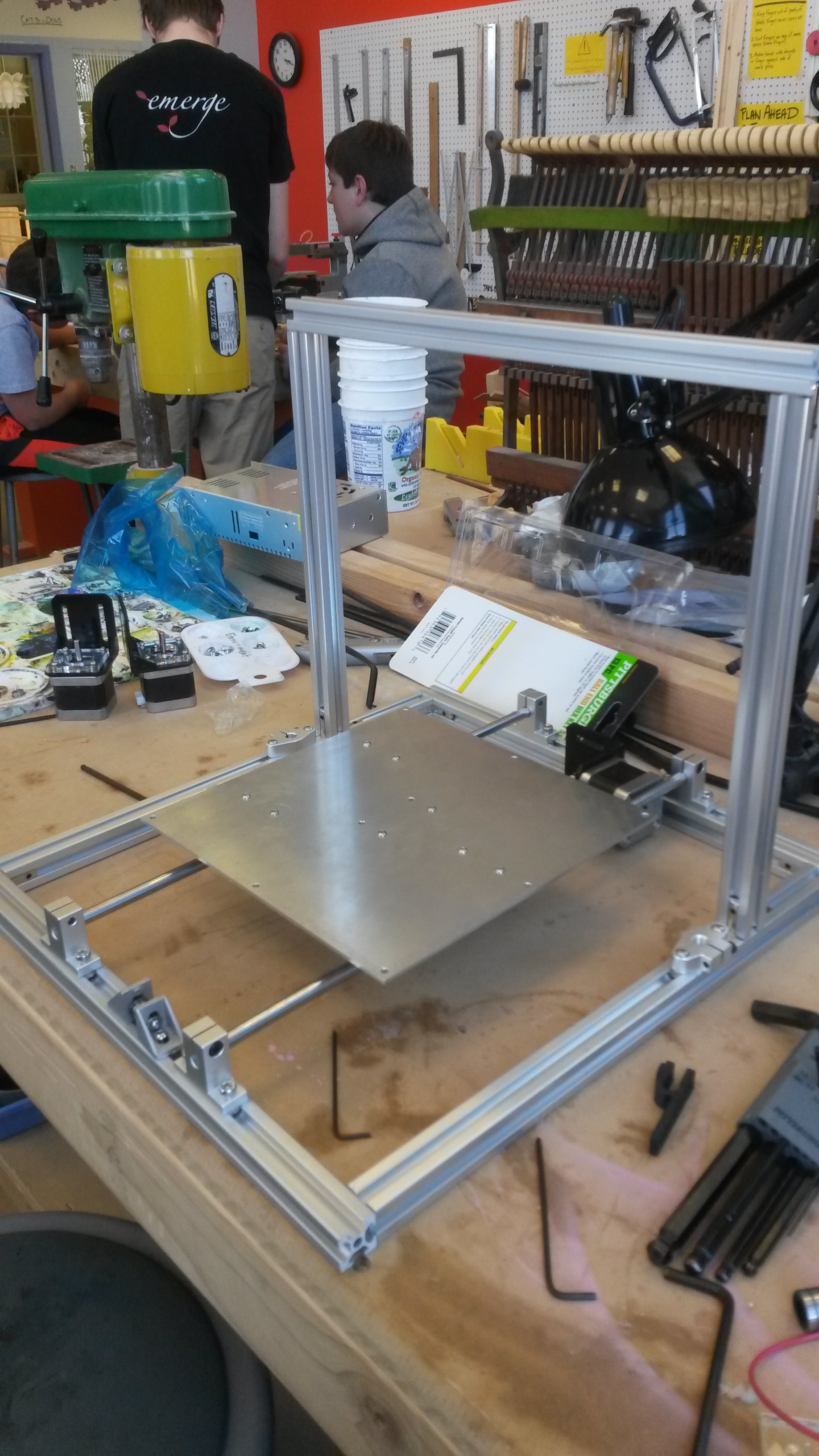

/As the tinkering space at Breakwater school continues to metamorphose into our Curiosity Lab, opportunities for young engineers to make, discover, experiment and invent are made possible. March 18 and 19 the Open Bench Project partnered with Breakwater school to offer a 3d printer building workshop. Yes. Printer building. With the help of experienced workshop leaders, participants were offered a chance construct their own aluminum Folger Tech Prusa i3 3d printer together.

Breakwater’s tinkering essentialist and workshop facilitator Shaun Aylward tells us more:

When I told students we’d be hosting a 3D printer building workshop in the tinkering studio, the most frequent response was a look of vexation. 3D printing, yes please, amazing. 3D printer building? You must be kidding.

But no. Open Bench Project swooped into the studio over the weekend and showed us just how real a possibility this is. After all, like a car or a washing machine, a guitar or that sleek chair at Ikea, 3D printers are made by people. Whyever not by us?

Saturday morning, March 18th. A menagerie of electronic parts explodes out of seven densely packed cardboard boxes, coating every surface in the Curiosity Lab with motors, PCB’s, wires, and extruded aluminum. It’s the big bang of miscellania. Within minutes of unsealing the kits, a whir of spinning minds and spinning allen wrenches spools up and continues all weekend, interrupted by life’s necessities only, and then only partially.

Sunday, late afternoon. The first 3D printer comes to life . . . for a brief moment. A puff of smoke and unhappy electronic noises announce the mistake; the motor drivers have been installed upside down. The Arduino is probably fried. After a weekend of messing up, pulling apart, and trying again, however, the stalwart engineers have steeled themselves against the disappointment of failure. Thirty minutes later they plug it in again and this time, no smoke, no snap of electric catastrophe. The two young makers, brothers, type commands on a computer and watch the extruder move back and forth.

There is much still to do before any of the printers knocked together during the workshop begin depositing thermoplastic in meaningful ways. As Jake Ryan of Open Bench would put it, we’ve built the rock. Now we must bring the rock to life. And finally, we must make the rock behave.

Enjoy the photos from the weekend’s workshop in the Curiosity Lab. The first of many.